| |

|

Ribbed Smoked Sheets

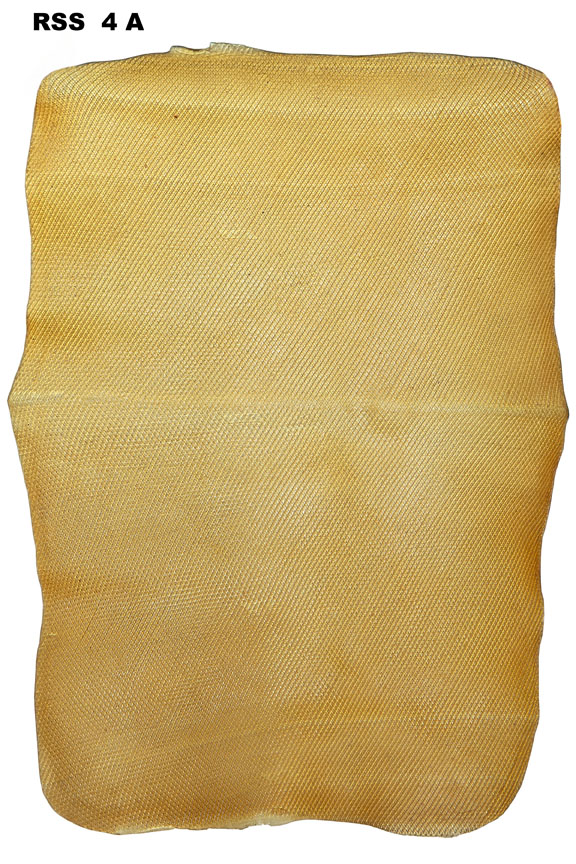

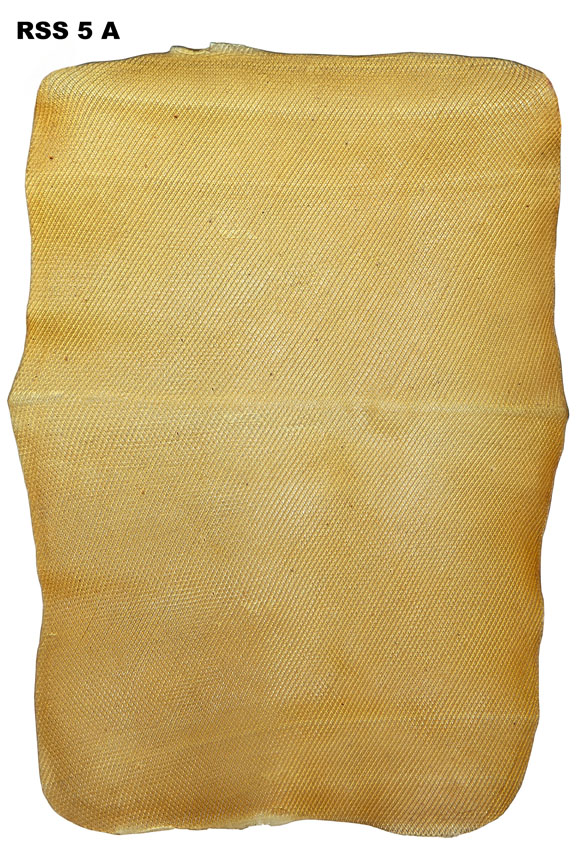

Ribbed Smoked Sheets (RSS) are coagulated rubber sheets processed from fresh field latex sourced from well managed rubber plantations adopting modern processing methods. The grades available are shown in the table. The higher grades RSS 1x to RSS 3 are mainly used for manufacture of products for medical, pharmaceutical and engineering. The lower grades of RSS 4 and 5 are generally used for the manufacture of automobile tyres, re-treading materials and all other general products. RSS 3 and RSS 4 are the preferred raw material for radial tyres. Quality of Ribbed Smoked Sheets is ascertained as laid down in Green Book Standards.

In India, RSS grades are packed as 50kg bales in polythene cover and as 110kg crates as per the requirements of the buyer. Ribbed Smoked Sheets are graded according to the standards as per IS – 15361-2003 by visual comparison method. Normally this is done by observation of sheets held against light, when the obvious defects become apparent.

Cluster groups formed among rubber farmers in India, popularly known as “Rubber Producers Societies (RPS) are involved in the production of high quality grades in their group processing centres for domestic and world markets. High grade sheets are produced in individual farms as well.

Domestically produced RSS rubber grades are in good demand for tyres and other product manufacture indicating their quality and market acceptability.

| RSS 1X - | Oxidized spots or streaks, weak, heated, undercured, over-smoked, opaque and burnt sheets are not permissible in this grade. The rubber must be dry, clean, strong, sound and evenly smoked, and free from blemishes, specks, resinous matter (rust), blisters, sand, dirty packing and any other foreign matter. Small pinhead bubbles, if scattered, will not be objected to. |   |

| RSS 1 - | Oxidized spots or streaks, weak, heated, under cured, over-smoked, opaque and burnt sheets are not permissible in this grade. The rubber must be dry, clean, strong, sound and evenly smoked, and free from blemishes, specks, resinous matter (rust), blisters, sand, dirty packing and any other foreign matter, except slight specks. Small pinhead bubbles, if scattered, will not be objected to. |   |

| RSS 2 - | Oxidized spots or streaks, weak, heated, undercured, over-smoked, opaque and burnt sheets are not permissible in this grade. The rubber must be dry, clean, strong, sound and free from blemishes, blisters, sand, dirty packing and all other foreign matter other than specified above as permissible. |   |

| RSS 3 - | Slight blemishes in color, small bubbles and small specks of bark permissible in this grade. Oxidized spots or streaks, weak, heated, under-cured, over-smoked, opaque and burnt sheets are not permissible in this grade. The rubber must be dry, clean, strong, sound and free from blemishes, blisters, sand, dirty packing and all other foreign matte r other than specified above as permissible. |   |

| RSS 4 - | Medium size bark particles, bubbles, translucent stains, slightly sticky and slightly over smoked rubber are permissible. Oxidized spots or streaks, weak, heated, under-cured, over-smoked, and burnt sheets are not permissible. The rubber must be dry, clean, strong, sound and free from blemishes, blisters, sand, dirty packing and all other foreign matter other than specified above as permissible. |   |

| RSS 5 - | Large bark particles, bubbles and small blisters, stains, over-smoked, slightly sticky rubber and blemishes are permissible. Slightly under-cured rubber is permissible. Weak, heated, burnt, oxidized spots or streaks are not permissible. The rubber must be dry, firm and free of blisters. Dirty packing, sand and all other foreign matter other than specified above is not permissible. |   |

| Air Dried Sheets- | This is a light colored sheet prepared in the same way as ribbed smoked sheets but dried in a shed or tunnel using hot air instead of smoke. As color of the sheets is an important consideration, use of sodium bisulphate which inhibits enzymic discoloration and lightens the color is necessary. Usually a calculated volume of a solution of sodium bisulphate is added in the bulking tank so as to get 1.20 g of it in one kg of dry rubber. Air dried sheets can be used as substitutes for Pale Latex Crepe and hence this type of sheets may fetch a better price compared to smoked sheets. | |

Ribbed Smoked sheets (RSS grades) specification as per Green Book

Parameters |

RSS 1X |

1 |

2 |

3 |

4 |

5 |

Air Dried sheets

Froathy sheets

Partly/fully skim latex sheets

Wet sheets

Bleached (pale) sheets

Sand

Dirty packing

Oxidised spots

Streaks

Weak sheet

Heated Sheet

Burnt Sheet |

No

|

Sheets to be – Dry

“ “ - clean

“ “ - strong

“ “ - sound |

Yes |

Covering sheets |

Same or higher grade |

Holes in Wrapper sheets |

Use double wrapper sheets |

Bale coating & stenciling |

As per the Green Book standard |

Resinous matter (rust) |

No |

No |

slight |

Less than 5% of sample |

Less than 10% of sample |

Less than 20% of sample |

Less than 30% of sample |

Mould/Dry mould |

Free of Mould

Very slight traces of dry mould on wrappers or bale surface adjacent to wrapper.

(No penetration) |

+slight on wrapper & bale surface & interior |

less than less than less than less than

5% of 10% of 20% of 30% of

sample sample sample sample |

Blisters |

No |

Slight |

Other foreign matter |

No ( other than specified, if any) |

Bubbles/pin head bubbles |

Scattered small pin-head bubbles |

Small bubbles |

Medium size |

Large |

Transluscent stains |

No |

Medium size |

Yes |

Stickiness (Tackiness) |

No |

slight |

Under-cured |

No |

slight |

Over smoked |

No |

Slight |

Yes |

Opaque sheets |

No |

|

|

Evenly smoked |

Yes |

Slightly over smoked |

Over smoked |

Blemishes |

No |

Yes |

Specks |

No |

Slight |

Slight specks of bark |

Small specks of bark |

Medium size bark |

Large bark particles |

Stains |

No |

Small stains |

Prohibitions applicable to all grades of RSS

- Block, cuttings, or other scrap or frothy sheets

- Weak, heated or burnt sheets

- Air dried or smooth sheets

- Wet, bleached, under-cured and virgin rubber

- Rubber that is not completely visually dry at the time of buyer’s inspection

- Skim rubber made out of skim latex used in whole or part in the production.

Defects not permitted in any RSS grade

- Opaque sheets

- Wet mould

- Weak sheets

- Heated sheets

- Burnt sheets

- Oxidised sopts or streaks

- Airdried sheets

- Frothy sheets

- Dirty packing sand

- Other foreign matter

|

|

Quality Specs

|